January 18, 2023

Holiday Season 2022 Went Smoothly: But Supply Chain Technology Is Still Lagging

Tags:

Holiday Season 2022 Went Smoothly: But Supply Chain Technology Is Still Lagging

This article originally appeared on TechCrunch on Dec. 22, 2022

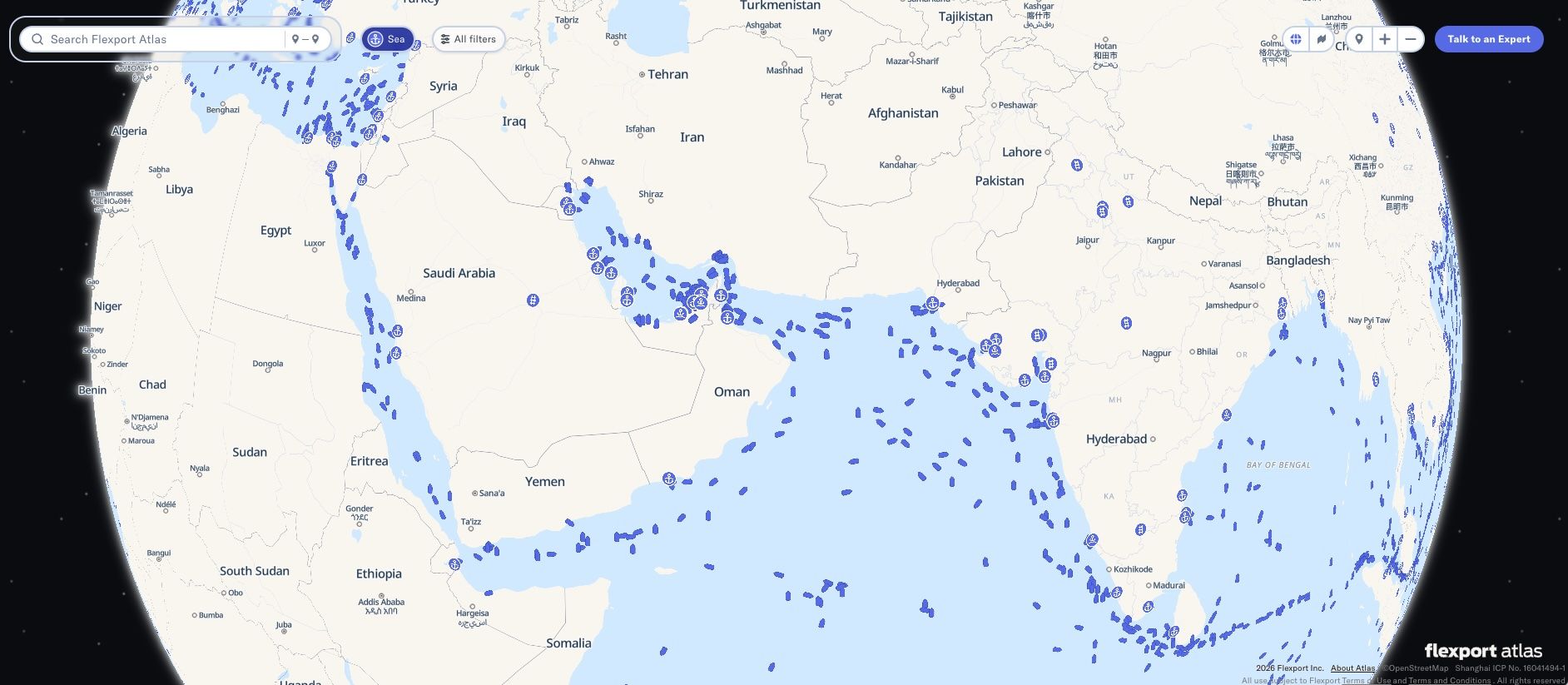

Compared to last year’s holiday season, major maritime trade routes are operating relatively smoothly, while shipping rates are returning to Earth and ports are moving cargo at a steady clip.

Now that’s all good news for businesses and consumers worried about inflation and talk of recession, but those improvements are misleading.

A deeper look reveals global shipping speeds aren’t back to pre-pandemic levels, and serious challenges persist in supply chains that foreshadow even bigger problems. If we don’t act and improve shipping technologies, the logjams we’ve had to endure for the past two years will become commonplace.

New Season, New Problems

Businesses are still taking too long to ship their goods from Asia to the United States or Europe. While it’s better than the record delays we saw during the height of the pandemic, it still takes 69 days for businesses to ship goods from China to U.S. ports, approaching double the time it took before the pandemic. This is happening against the backdrop of a slower economy, and shipping company Maersk is forecasting a 2% to 4% drop in world demand for containers this year.

This year’s improvements in shipping largely reflect a pullback in consumption rather than any improvement in the underlying infrastructure.

A host of other problems, both new and familiar, are plaguing global logistics in 2022 such as volatile fuel prices, protracted labor negotiations and worker shortages.

Meanwhile, businesses large and small are signaling problems. Retail giants such as Target and Wal-Mart are struggling with inventory build-ups ahead of the holiday season, as many companies were hit by a surge in imports that suddenly arrived after shipping delays eased up. This will squeeze profits and cause unrest among investors while creating pain for small and medium businesses, which are finding it hard to reserve space at warehouses already overrun with goods from big retailers.

Fundamental Weaknesses

All of these issues expose fundamental weaknesses in the supply chain, many of which point to one persistent problem: Shipping remains surprisingly analog, composed of a fragmented value chain that’s vulnerable to unique and sometimes chaotic market forces.

Without the kind of data-driven insights that other industries employ, companies have little visibility into the capacity, location and arrival dates for their goods. Additionally, many ports are technologically backward and the most important ones are run by different commercial entities or governments with varied cultural norms, currencies, customs requirements and other challenges.

Each of these factors places the logistics industry at an inflection point: Solve these inefficiencies and create an ecosystem that’s more resilient and more transparent or risk the health of global trade.

Leveraging Data

Fortunately, the data available today is rich beyond measure, and we also have the tools to leverage it in ways that can boost efficiency. We can collect data from myriad points along logistics routes—optical character recognition scans at factories, sensors at port terminals, GPS readings from truck and warehouse—and feed them into machine learning models that will help us better predict where goods will be and the resources we’ll need to carry them to the next phase.

By unlocking and linking this data, the industry will help businesses achieve everything from finding and filling excess shipping capacity anywhere in the world to identifying the most efficient trade routes and methods that will reduce their carbon footprint.

Failure to do so will prove disastrous. This year’s improvements in shipping largely reflect a pullback in consumption rather than any improvement in the underlying infrastructure. When consumers pick up the pace of buying again—and they will; forecasts show freight activity climbing 50% by 2050 in the U.S. alone—shipping companies and ports will be strained to the point that we’ll see problems like we saw in 2020 and 2021.

The problem goes well beyond corporate profits and holiday shopping delays. The shipping industry is the lifeblood of the global economy: decades of moving high volumes of goods at low cost have arguably lifted more people out of poverty than any other industry.

But we haven’t learned from last year’s problems and are allowing a false sense of improvement to distract us from what needs to be done. The fix isn’t easy, but it’s within reach. We must act now and implement the kind of technological changes most other industries adopted long ago.

Related content

![Port GettyImages-1600x800]()

BLOG

New Year, New Supply Chain Landscape? Don't Expect A Return to Normal Right Away in 2023