May 10, 2023

What Storm? How to Take Advantage of Today’s Calm Seas

Tags:

What Storm? How to Take Advantage of Today’s Calm Seas

Director, Program Management - SMB Experience

Just about a year ago, we shared a few ways small businesses could manage the volatile freight market in order to stay ahead of their competition. A lot has changed in a year—port congestion is approaching negligible, factories in Asia are back to nearly full capacity, and for most, global logistics are looking a lot like 2019.

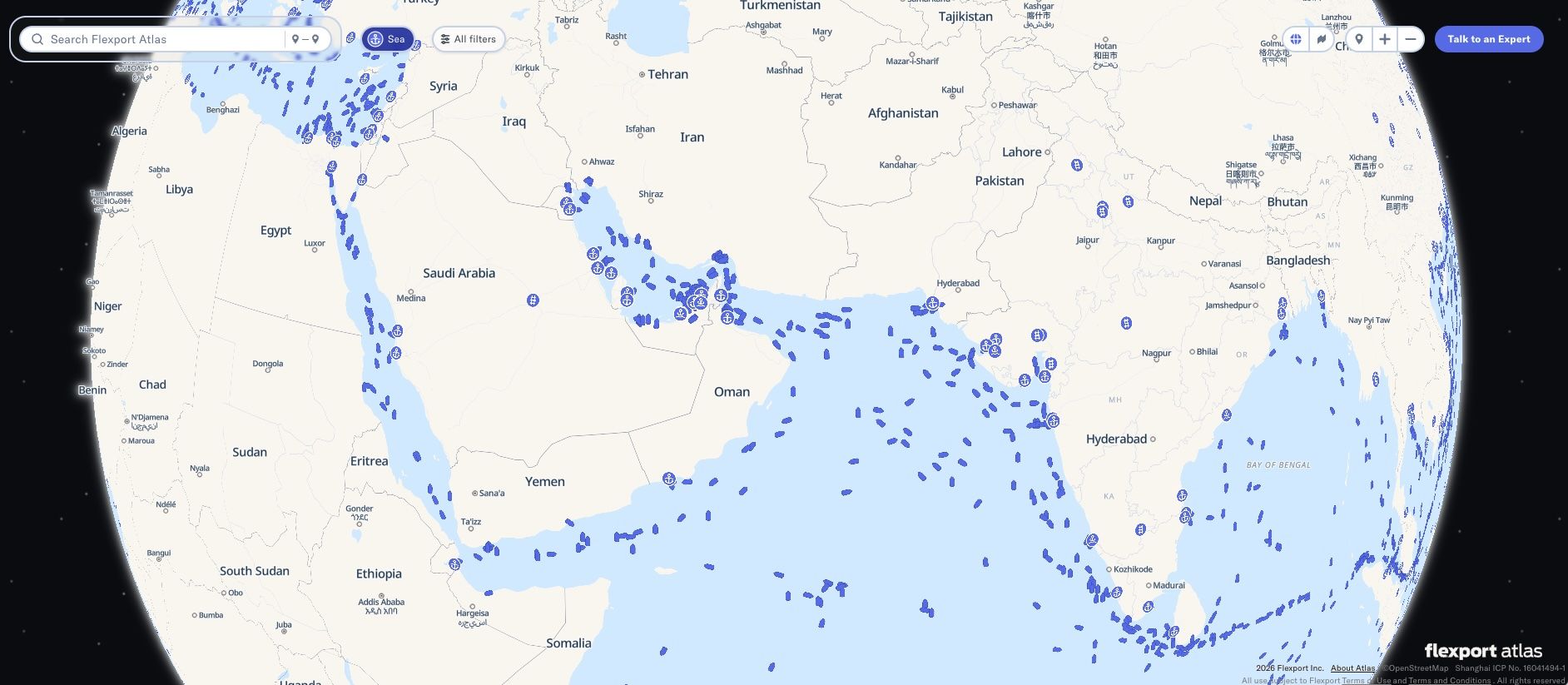

That doesn’t mean it’s time to sit back and put your supply chain on autopilot, however. On the contrary, this is the opportune time to invest and assess if you have the right partners, tech stack and internal processes to handle whatever comes next. We can’t say when the next ocean vessel may block a major canal, can we?

We know that “getting ahead of things” is easier said than done, which is why we’ve identified three focus areas for SMBs as we head into the back half of 2023.

1. Advanced Planning Equals Better Cost Control

One of the only ways to recoup losses from last year is to control your costs now. Take advantage of the low ocean rates for the majority of your freight, either by consolidating multiple shipments into a single full container load (FCL) shipment, or by using a less-than container load (LCL) service. Having customer demand data at hand will allow you to time those shipments appropriately to remain in stock without suffering overages or stockouts.

The same customer demand data used to inform your inventory plan will also help you identify which SKUs are selling faster or are at higher risk of going out of stock. Or if you need to rush in seasonal products to meet customer demand, like pool floats or barbeque accessories for summer. If you can differentiate amongst those SKUs, you can start to get creative with how you book them out by leveraging consolidation services that can provide faster transit times and lower costs, etc.

And speaking of your inventory plan, it needs to account for not only how much inventory you’re going through, but how fast you’re selling through it. This understanding of inventory turnaround is what will allow you to time your orders more efficiently, avoiding last minute priority orders for example. It’s also what will allow you to avoid exacerbating the current overstock situation many are facing.

2. Diversification Brings A Multitude of Benefits

This period of relative calm is the ideal time to work on diversifying your own partnerships, risks, mode options, and more. By setting in place a broad network of suppliers, freight and logistics partners, and even multiple destination warehouse options, you’re ensuring a high level of business resiliency.

Spreading out your volume, whether across lanes, modes, or even shipment sizes can help keep your inventory levels where you want them rather than where a fickle market dictates they be. If you’re using ocean freight for the majority of your cargo, then experience a surprise rush, you can always expedite restocking by using air freight for a small volume to cover you. Or you can consider keeping some backstock in a separate, more remote—and therefore cheaper—warehouse that you can pull from to fill in any gaps that appear.

3. Staying Flexible Can Yield Further Gains

Flexibility will mean something different for everyone. For an SMB retailer it can mean having small amounts of inventory stashed nearby for your best-selling SKUs, or having your supplier be ready to mail some in via air should you experience a surprise rush. Beyond that, keep an eye on the news and stay flexible on routings—traditional routings aren't always the best as droughts, floods, and strikes can hit any normal trade route at any time.

Expanding your existing network of partners, suppliers, and third-party logistics (3PLs) providers to include alternatives—say a supplier in a different country to your primary one, or a new 3PL who offers more route options—means that should things go sideways (who are we kidding, it’s more a matter of when), you’re prepared to shift volume. From one factory to another, ocean to air, or FCL to LCL. You can even pull that remote backup inventory and put it in play.

We hope these suggestions have given you a starting point on your own journey toward stabilizing your supply chain to deliver better long-range outcomes. Take advantage of current market conditions to build your supply chain resilience and find opportunities to maximize efficiency now. Your supply chain should be a source of value, not a source of risk—it’s time to take back control!

If you’re a fast-growth ecommerce or retail brand, creating demand is just the start. You’ll need to have an agile, resilient supply chain to eliminate backorders, waitlists, and stockouts so you can deliver on that demand. Learn more about how Flexport can help you keep your shelves stocked and customers happy with the end-to-end supply chain tracking, agility, and resilience you’re looking for.

About the Author

Director, Program Management - SMB Experience

Related content

About this author